Essential Tips for Maintaining Air Compressors on Semi Trucks

- fryejs91

- Sep 5, 2025

- 4 min read

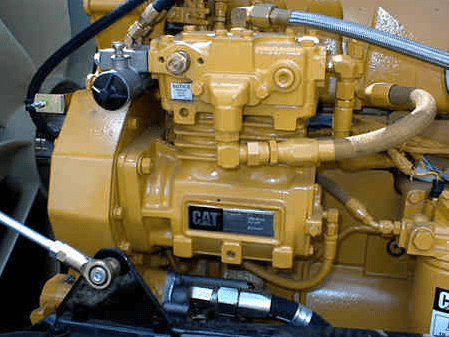

Keeping air compressors in good shape on semi trucks is vital for performance and longevity. These compressors help operate important systems like brakes and air suspension. If neglected, they can lead to expensive repairs and costly downtime. This post offers practical tips to maintain air compressors effectively, helping you keep your truck running smoothly.

Understanding the Importance of Air Compressors

Air compressors generate compressed air, necessary for pneumatic systems in semi trucks. For instance, without a functioning air compressor, the braking system might fail, putting drivers and others at risk. A well-maintained air compressor ensures smooth operation, enhancing safety and comfort during long hauls.

Maintaining these crucial components can prevent problems like air leaks, poor performance, and even complete failures. For truck owners, understanding this importance is the first step to prioritizing maintenance.

Regular Inspection

Regular inspections are among the simplest yet most effective ways to keep air compressors in top condition. Truck owners should routinely check the compressor for signs of wear and tear.

Visual Checks

Start with a visual inspection of the compressor and its components. Look for oil leaks, cracks, or corrosion. Make sure hoses and fittings are secure and free from damage. For example, finding and fixing a small oil leak can save approximately $300 in repairs before it worsens.

Listening for Unusual Sounds

While the truck is running, pay attention to sounds coming from the compressor. If you hear grinding, hissing, or excessive noise, it could indicate a serious problem. Don’t ignore these signs; addressing them early can prevent major issues.

Change the Oil Regularly

Air compressors need regular oil changes to keep running smoothly. The oil lubricates moving parts and helps manage heat.

Recommended Oil Change Intervals

Refer to the manufacturer’s guidelines for oil change intervals, which generally recommend changing oil every 500 to 1,000 hours of operation. However, if your truck is frequently in extreme environments or heavy loads, you might need to change it more often.

Choosing the Right Oil

Always use the manufacturer-recommended oil. Using the wrong oil can lead to increased wear. For example, switching from synthetic to conventional oil can significantly impact performance and might reduce the life of the air compressor by 25% or more.

Monitor Air Filter Condition

The air filter in the compressor is crucial for maintaining air quality. A dirty or clogged filter can limit airflow, resulting in decreased performance.

Regular Cleaning or Replacement

Check the air filter frequently and clean or replace it as necessary. A clean air filter can improve airflow by up to 20%, directly benefiting compressor performance.

Signs of a Clogged Filter

If you notice a loss of power or increased fuel consumption, inspect the air filter. Ignoring a clogged filter can not only degrade performance but may also increase fuel costs by as much as 10%.

Check for Air Leaks

Air leaks can drastically reduce the efficiency of an air compressor. Even a small leak can cause a significant loss of pressure.

Identifying Leaks

To check for air leaks, listen for hissing sounds around the compressor and connections. You can also apply soapy water; bubbles form at the source of any leaks.

Repairing Leaks

If you discover leaks, address them promptly. Repairs may involve tightening connections or replacing damaged hoses. Fixing leaks can improve system efficiency by up to 30%, saving substantial fuel costs.

Maintain Proper Belt Tension

The drive belt connects the air compressor to the engine, making proper tension crucial for optimal functionality. A loose or worn belt can cause reduced performance.

Checking Belt Condition

Inspect the drive belt for wear signs, such as cracks or fraying. Ensure it’s tensioned correctly according to manufacturer specifications. A loose belt not only impacts performance but can shorten the compressor’s lifespan.

Adjusting Tension

If the belt is loose, adjust its tension as required. Properly tensioning the belt helps the compressor work efficiently and can promote an extended lifespan.

Keep the Compressor Clean

Debris can accumulate on the compressor, harming its efficiency. Regular cleaning is essential.

Regular Cleaning

Use a soft brush or cloth to clean the compressor’s exterior. Avoid harsh chemicals that might damage parts.

Protecting from Contaminants

Whenever it’s possible, park the truck in cleaner environments to limit exposure to dirt. Keeping the compressor clean helps maintain its functionality over the long term.

Schedule Professional Maintenance

While regular checks can be done by truck owners, it’s wise to schedule professional maintenance. Trained technicians can spot issues that may be missed during routine inspections.

Finding a Qualified Technician

It’s essential to locate a technician with experience in air compressor maintenance. They possess the tools and expertise for comprehensive inspections and repairs.

Keeping Records

Maintain detailed records of all maintenance performed. This documentation helps track the condition of the compressor and ensures nothing is overlooked during servicing.

Final Thoughts

Regular maintenance of air compressors on semi trucks is critical for safety, efficiency, and durability. By following these straightforward tips, truck owners can keep their compressors in excellent condition and avoid costly repairs. Regular inspections, timely oil changes, air filter upkeep, and professional servicing create a solid maintenance plan.

Investing in the maintenance of air compressors leads to smoother operations and peace of mind on the road.

Comments